Are you looking for Wheel Alignment for your vehicle?

Welcome to Mill Tyres in Boston and thank you for taking the time to look at our information page about wheel alignment (tracking).

The wheel alignment is not necessarily on the routine checklist for most motorists. There are good reasons though to keep an eye on your vehicle’s chassis.

In everyday life, the suspension has to cope with heavy loads, and high impacts: driving over kerbs, through potholes and other road damages have a substantial impact on the chassis mechanics.

The resulting forces cannot always be tolerated by the car. And so it often happens that track, lintel or other chassis parameters move with time.

If you suspect a wrongly adjusted chassis, you should not hesitate and have a wheel alignment carried out by a specialist. The change in geometry of a vehicle axle can lead to a lot of issues, and can seriously affect your driving safety and tyre wear.

Wheel alignment and tracking - Avoid hazards

What is the purpose of the wheel alignment?

The wheel suspension of a car consists of several components. These ensure that the wheels can move up and down over the spring paths.

Also, the steering must be possible at all times. By driving the car, different forces act on the wheels. As a result, the wheels must be mounted in such a way that they always roll with the entire running surface of the tyres on the road, even at a higher load. This is set using toe, caster and camber. All this is referred to as the track setting.

In the case of axle measurement, the toe-in is measured in the first step on the front axle. This means that the two front wheels are not exactly parallel to each other, but rather trapezoidal. Therefore, the term "axis geometry" also comes into play. At the front, the distance between the wheels is a few millimetres less than on the side of the axle. This is because the wheels drift slightly outwards when loaded. Then they run parallel again.

The caster means that the stub axles are not at a 90-degree angle. The steering knuckle is tilted backwards by about two to three degrees. This causes the wheels to be pulled and not pushed.

In the case of wheel alignment, the so-called lintel is also an important measure. In a vehicle, the wheels are never exactly vertical. At the top, they slope a few degrees outwards. When driving the car, the forces that occur will cause the wheels to roll vertically.

The consequences of a wrong track setting can be felt immediately by the driver. Depending on the setting, it leads to under-steering or over-steering in curves. Understeering means that the car continues to drive straight ahead despite steering. When over-steered, the stern breaks out during a journey through a curve. This is not only unpleasant but also dangerous.

Even minor changes to the axle geometry are visible on the tyres. As soon as the profile of the tire only wears on one side, a wheel alignment and tracking should be carried out in a workshop.

This is how it works

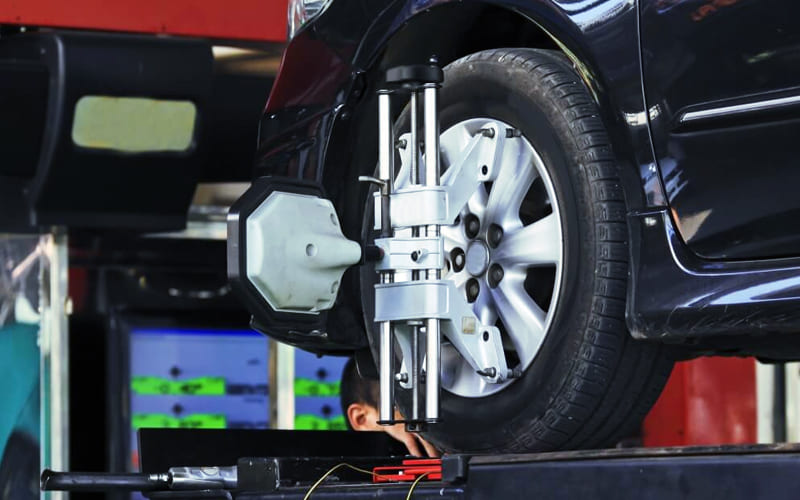

Here at Mill Tyres, we only use the latest and most accurate technology – the Hunter Hawk Eye laser system.

Our alignment specialists will take your vehicle on a special scissor lift ramp and mount reflector clamps with small points on each wheel. The position of these points is then captured by a camera and converted into a 3D model, which will be showing on the computer, and the results will also be printed out for you before and after the alignment. If a deviation of the wheel geometry is determined, a new adjustment is performed, for example, on the tie rods. In case of a defect, we repair the damage.

For more detailed information, please have a look at the wheel alignment video on our website or speak to our friendly experts directly.