Get a Call today Call Us

Are you looking for Suspension Service for your vehicle?

Hello and welcome to Mill Tyres in Boston

Thank you for taking the time to have a look at our little information page about vehicle suspensions.

The springs, which carry the largest part of the suspension in a car, serve to compensate for unevenness on the road. If they were not present, vibrations from the road would be transmitted more intensively to vehicle and occupants. The springs therefore also serve security.

You will learn how a landing gear spring is installed and functioning, which can show signs of a defect and what you should consider during a repair.

Design and function of a landing gear spring

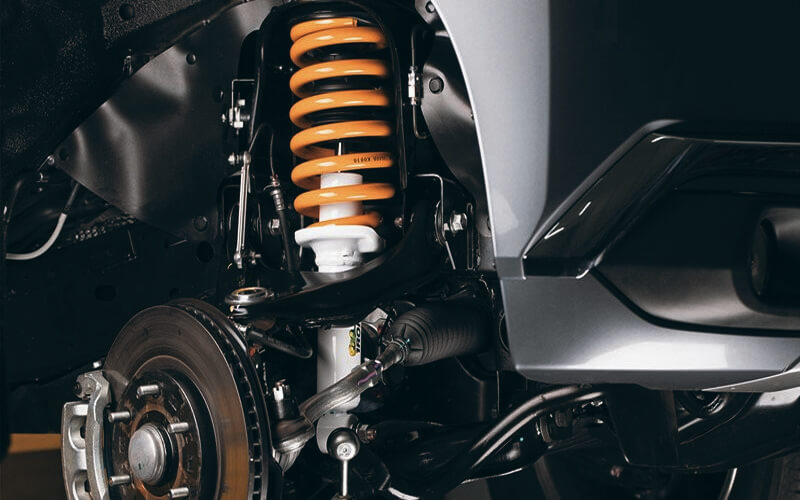

The spring is positioned behind the wheel. Frequently, the design of the MacPherson strut is used in the vehicles. It is similar to the construction of a screw and is equipped with a spring plate at the upper and lower end.

In the landing gear spring (at least concerning the front axle) the so-called shock absorber, which is screwed on the top side with the dome bearing, runs. On the lower side, on the other hand, is the spring strut, on the support joint of which the transverse link is connected. You will find information on the shock absorber in a separate guide.

If the car moves on an uneven road, the different heights of the springs are compensated as quickly as possible. If this were not the case, the components of the vehicle and the passengers would be exposed to any vibration. The driving comfort, the safety and the longevity of the car would suffer greatly. The landing gear spring can be used to determine how 'soft' or 'hard' the driving characteristics of a vehicle are.

If the travel of the spring is long, it is also possible to pass through large shock-absorbers in the passenger compartment without great vibrations. However, this is countered by a less optimal curve behavior.

Wear of the spring

The most common reason for the failure of the springs is the fatigue of the material. The higher the long-term load on the vehicle spring, the faster a spring breakage can occur.

Material errors also play a major role. If a small crack is present in the spring, it serves as a potential fracture site. Frequently such a break occurs at the moment when the car passes through a particularly deep slouch.

Checking the bearing play of the spring strut

Our Mill Tyres mechanic checks the functionality of the removed landing gear spring. Since the spring strut is moved along with the steering, this is usually based on a support bearing in the so-called spring strut, which is also referred to as a dome bearing. This component thus represents the connection between the spring strut and the body and ensures the proper functioning of the spring.

To check a defect of the dome bearing, its play can be controlled.

For this, the affected wheel of a car is moved vertically and horizontally back and forth on the lifting platform. If the wheel can be easily pulled downwards and upwards and thus has a clear play, this is an indication for a knocked-out dome bearing. If the bearing is defective, it should be renewed immediately in order not to unnecessarily load adjacent components, such as the shock absorbers or the shock absorbers, and thus prevent a greater wear on the components.

These signs indicate a possible defect

The following is a selection of the most common symptoms:

Crack in feather

- The vehicle spring has a crack (visual inspection)

Steering restricted

- The steering does not work correctly - it can not be fully steered, for example

Unusual sounds

- When driving over unevenness, striking or rattling noises occur.

Change springs

To replace defective landing gear springs, the vehicle must be jacked up or placed on a lifting platform. After dismantling the tires and releasing the strut, various screws and other chassis components, the spring is usually removed from the spring strut using a special spring tensioner.

However, some manufacturers connect the vehicle spring and the shock absorber tightly together, so that the expansion is delayed or simply impossible. In this case, the expected costs increase enormously. It should be noted that the springs should always be changed in pairs.

Thus irregularities in the driving characteristics of the car are avoided.

Important note: The installation of a new spring requires not only professional know-how and special tools but also differs significantly in the respective vehicle types.

Since the landing gear, spring is one of the safety-relevant components of a vehicle, the installation of the springs should be better left to a specialist. Also, the spring, which is under tension.

Also, the spring that is under tension can cause serious injuries in the event of improper installation or removal.

Selection of suitable landing gear springs

Springs in original equipment quality are usually more expensive than cheaper models but promise a longer service life. Therefore, our Mill Tyres experts recommend that you should purchase new products from the vehicle manufacturer or trusted suppliers when buying new springs. A high-quality spring can last a lifetime.

What you should consider for the chassis spring in your car:

The effort for installing and removing the landing gear spring varies between the individual vehicle models and is significantly greater when the spring is firmly connected to the shock absorber.

The car body can wear out as the vehicle ages and finally break, which greatly reduces the driving comfort and the safety of the vehicle.

Due to the tensioning force of the spring, there is a risk of injury when the chassis spring is changed by hand

Have the repair carried out in a specialist workshop - come to see us - Mill Tyres suspension service in Boston.